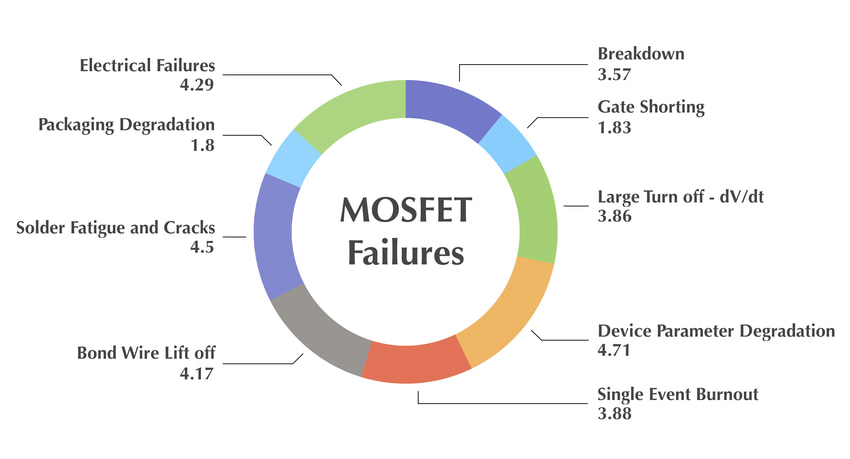

Cov txheej txheem ceev:MOSFETs tuaj yeem ua tsis tiav vim muaj ntau yam hluav taws xob, thermal, thiab kev ntxhov siab. Kev nkag siab txog cov hom kev ua tsis tiav no yog qhov tseem ceeb rau kev tsim cov tshuab hluav taws xob hluav taws xob txhim khu kev qha. Phau ntawv qhia ntxaws no tshawb txog cov txheej txheem ua tsis tiav thiab cov tswv yim tiv thaiv.

Feem ntau MOSFET Failure Modes thiab lawv cov hauv paus ntsiab lus

Feem ntau MOSFET Failure Modes thiab lawv cov hauv paus ntsiab lus

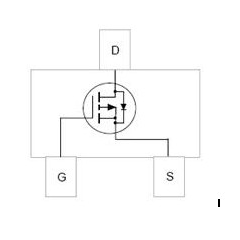

1. Voltage-Related Failures

- Lub rooj vag oxide tawg

- Avalanche tawg

- Punch-los ntawm

- Static paug puas tsuaj

2. Thermal-Related Failures

- Secondary kev puas tsuaj

- Thermal khiav

- Pob delamination

- Bond hlau lift-off

| Hom kev ua tsis tiav | Yam Tseem Ceeb | Cov cim ceeb toom | Txoj kev tiv thaiv |

|---|---|---|---|

| Rooj vag Oxide Breakdown | Tshaj VGS, ESD cov xwm txheej | Nce qhov rooj nkag | Lub rooj vag voltage tiv thaiv, ESD ntsuas |

| Thermal Runaway | Ntau dhau lub zog dissipation | Nce kub, txo kev hloov ceev | Zoo thermal tsim, derating |

| Avalanche tawg | Cov hluav taws xob hluav taws xob, tsis muaj kev sib hloov inductive | Cov khoom siv hluav taws xob luv luv | Snubber circuits, voltage clamps |

Winsok's Robust MOSFET Solutions

Peb tiam tshiab ntawm MOSFETs nta cov txheej txheem tiv thaiv qib siab:

- Txhim kho SOA (Safe Operating Area)

- Txhim kho thermal ua haujlwm

- Ua-hauv ESD tiv thaiv

- Avalanche-rated designs

Kev soj ntsuam ntxaws txog kev ua tsis tiav

Rooj vag Oxide Breakdown

Qhov tseem ceeb Parameter:

- Qhov siab tshaj plaws qhov rooj-qhov Voltage: ± 20V raug

- Rooj vag Oxide Thickness: 50-100nm

- Lub zog ntawm lub zog: ~ 10 MV / cm

Kev tiv thaiv:

- Siv lub rooj vag voltage clamping

- Siv series rooj vag resistors

- Nruab TVS diodes

- Cov txheej txheem PCB tsim nyog

Thermal Management thiab Failure Prevention

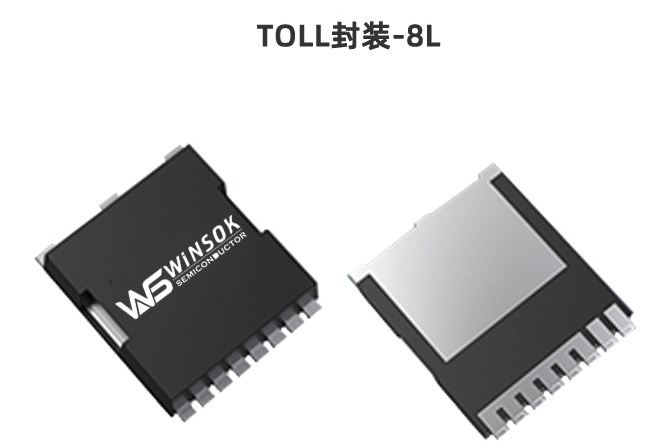

| Hom pob | Max Kev Sib Txuas Temp | Pom zoo Derating | Txias Solution |

|---|---|---|---|

| TSI-220 | 175 ° C | 25% | Heatsink + Ntxuam |

| D2 PAB | 175 ° C | 30% | Loj Copper Area + Xaiv Heatsink |

| TSO-23 | 150 ° C | 40% | PCB Copper Pour |

Qhov Tseem Ceeb Tsim Cov Lus Qhia rau MOSFET Kev Ntseeg

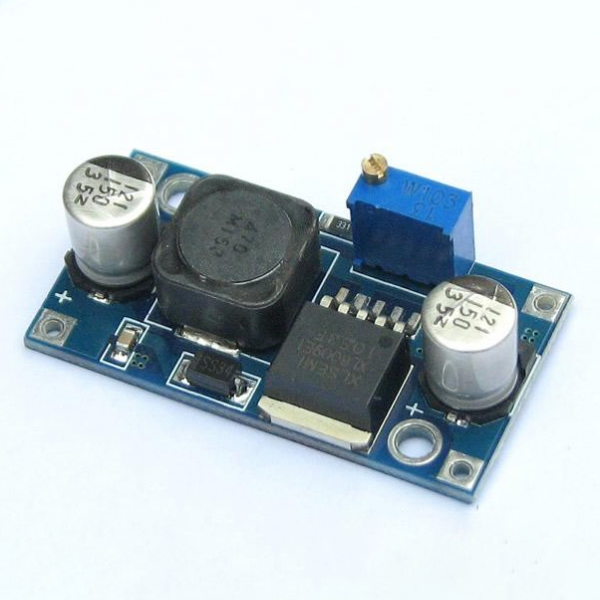

PCB Layout

- Minimize lub rooj vag voj cheeb tsam

- Cais lub zog thiab teeb liab hauv av

- Siv Kelvin qhov chaw txuas

- Optimize thermal vias tso

Kev tiv thaiv Circuit Court

- Siv cov hluav taws xob pib hluav taws xob

- Siv cov snubers tsim nyog

- Ntxiv kev tiv thaiv rov qab voltage

- Saib xyuas cov cuab yeej kub

Cov txheej txheem kuaj thiab kuaj

Basic MOSFET Testing Protocol

- Static Parameters Test

- Lub rooj vag voltage (VGS(th))

- Drain-source on-resistance (RDS(on))

- Gate leakage tam sim no (IGSS)

- Kev kuaj Dynamic

- Hloov sijhawm (ton, toff)

- Lub rooj vag them tus yam ntxwv

- Tso zis capacitance

Winsok's Reliability Enhancement Services

- Comprehensive daim ntawv thov tshuaj xyuas

- Thermal tsom xam thiab optimization

- Kev ntsuas kev ntseeg tau thiab kev siv tau

- Kev soj ntsuam tsis ua hauj lwm hauv chav kuaj kev txhawb nqa

Reliability Statistics thiab Lifetime Analysis

Kev ntsuas kev ntseeg tau tseem ceeb

FIT Rate (Failures In Sijhawm)

Tus naj npawb ntawm kev ua tsis tiav ib billion ntaus ntawv-teev

Raws li Winsok qhov tseeb MOSFET series nyob rau hauv nominal tej yam kev mob

MTTF (Lub Sijhawm Ua Tsis Tau)

Cia siab rau lub neej raws li cov xwm txheej tshwj xeeb

Ntawm TJ = 125 ° C, nominal voltage

Ciaj sia taus

Feem pua ntawm cov cuab yeej muaj sia nyob dhau lub sijhawm lav

Thaum 5 xyoos ntawm kev ua haujlwm tas mus li

Lub Neej Derating Factors

| Kev Ua Haujlwm | Derating Factor | Kev cuam tshuam rau lub neej |

|---|---|---|

| Kub (txog 10 ° C saum 25 ° C) | 0.5x ib | 50% txo |

| Voltage Stress (95% ntawm max ntsuam xyuas) | 0,7x ib | 30% txo |

| Hloov zaus (2x nominal) | 0,8x ib | 20% txo |

| Humidity (85% RH) | 0,9x ib | 10% txo |

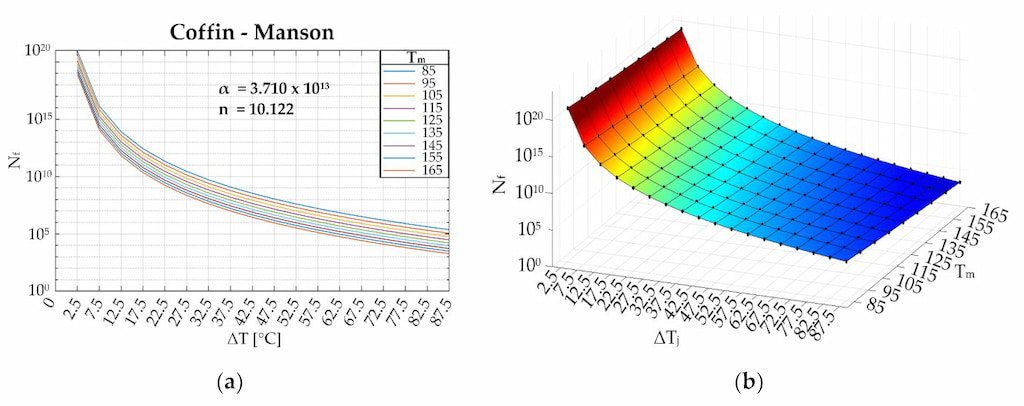

Lub Neej Muaj Peev Xwm Distribution

Weibull kev faib tawm ntawm MOSFET lub neej qhia txog kev ua tsis tiav thaum ntxov, kev ua tsis tiav, thiab lub sijhawm hnav

Environmental Stress Factors

Kub Cycling

Kev cuam tshuam rau kev txo qis hauv lub neej

Lub zog Cycling

Kev cuam tshuam rau kev txo qis hauv lub neej

Mechanical Stress

Kev cuam tshuam rau kev txo qis hauv lub neej

Cov txiaj ntsig ntawm Kev Ntsuam Xyuas Lub Neej Ceev

| Hom kev xeem | Cov xwm txheej | Duration | Failure Rate |

|---|---|---|---|

| HTOL (High Temperature Operating Life) | 150 ° C, Max VDS | 1000 teev | <0.1% |

| THB (Tsub Humidity Bias) | 85 ° C / 85% RH | 1000 teev | <0.2% |

| TC (Cycling kub) | -55 ° C rau + 150 ° C | 1000 cycles | <0.3% |